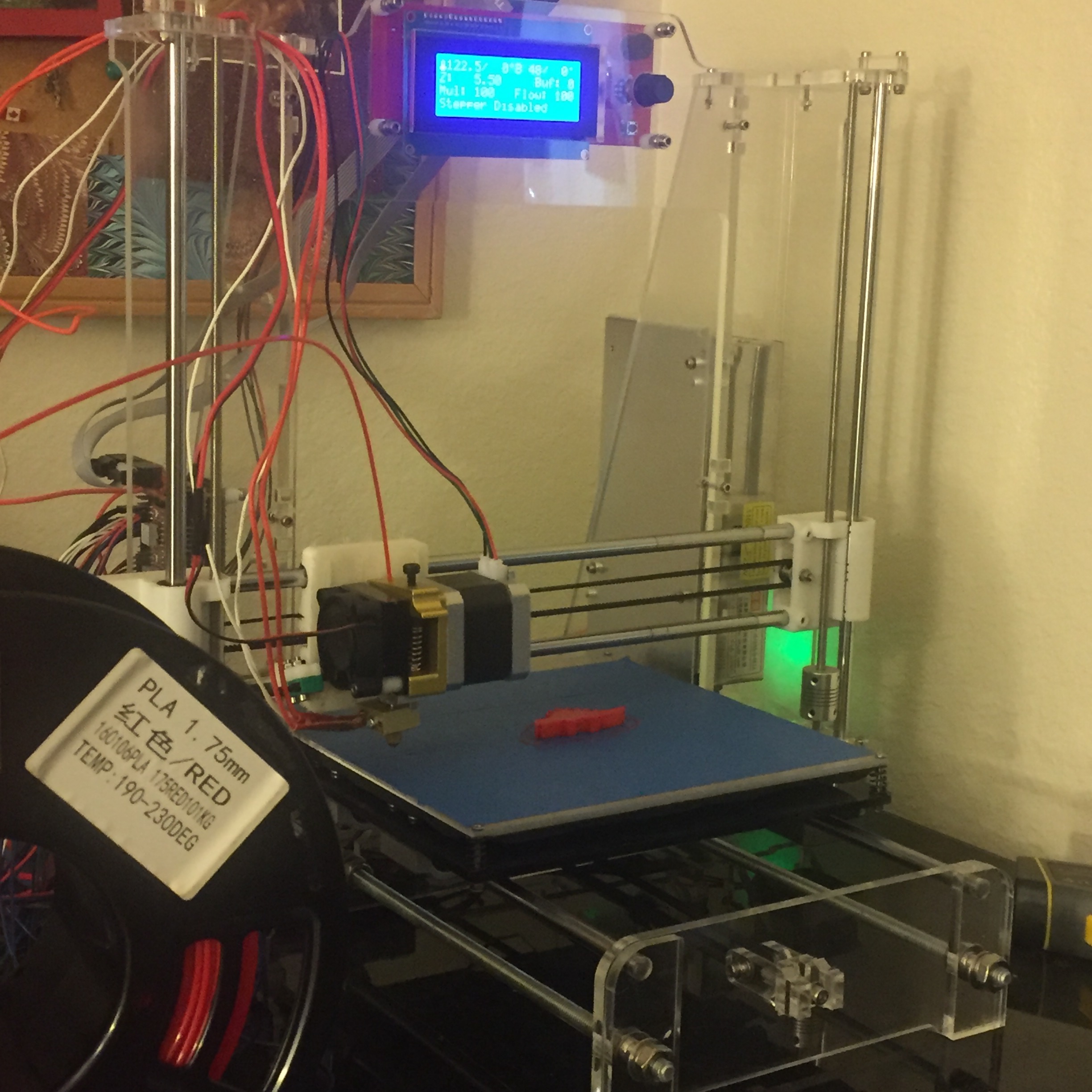

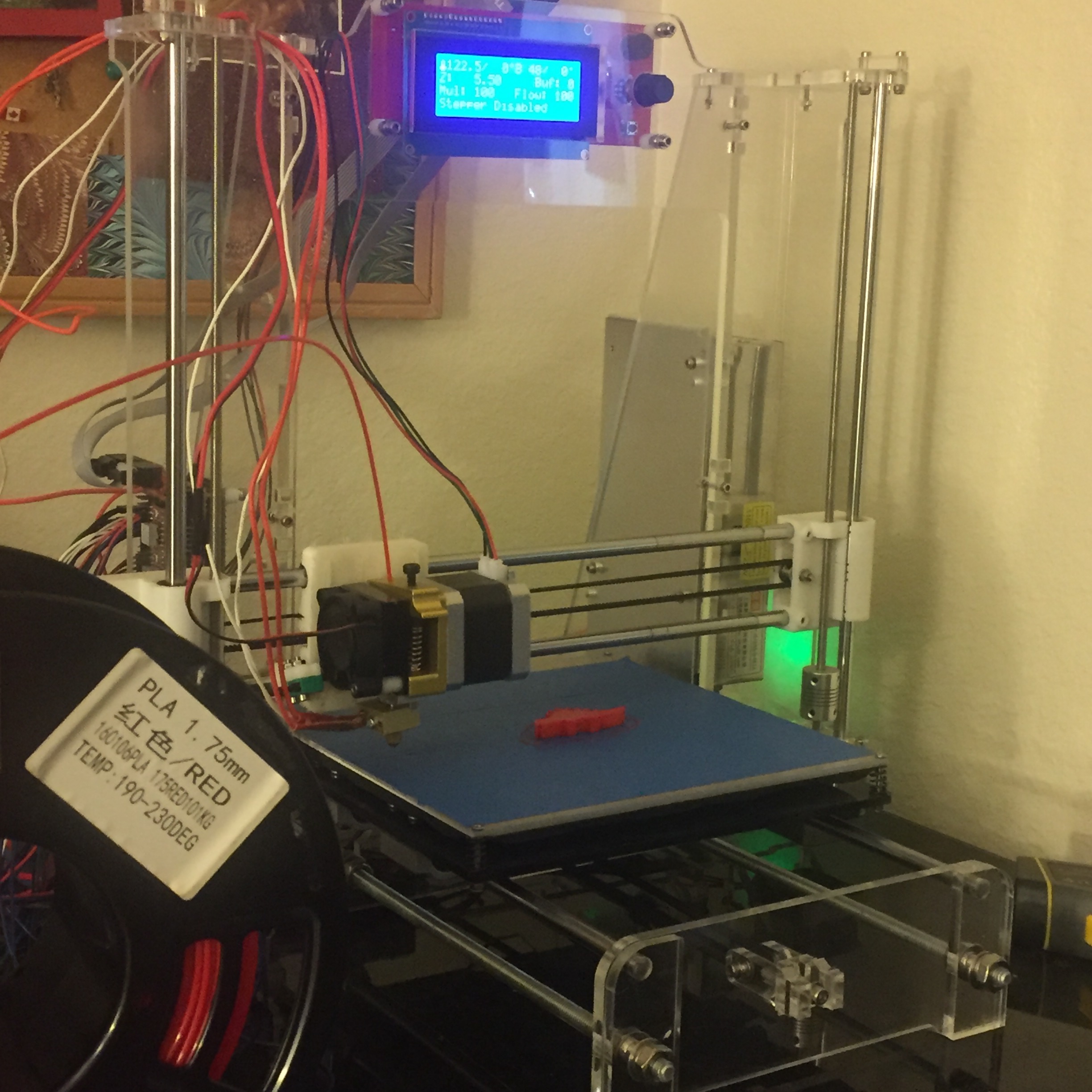

A year and a half ago, I ordered the cheapest Prusa i3 3D Printer kit I could find from 3D Printers Online Store. A few weeks later, two battered boxes full of wires and parts (some knock-off) arrived at my doorstep from China. I only recently got it working well enough to successfully print small items. It didn’t really take me over a year to complete; I was distracted by many other side projects. Uninterrupted, I think I could have finished the printer with 2 months of weekends, devoting 3-5 hours per weekend.

A year and a half ago, I ordered the cheapest Prusa i3 3D Printer kit I could find from 3D Printers Online Store. A few weeks later, two battered boxes full of wires and parts (some knock-off) arrived at my doorstep from China. I only recently got it working well enough to successfully print small items. It didn’t really take me over a year to complete; I was distracted by many other side projects. Uninterrupted, I think I could have finished the printer with 2 months of weekends, devoting 3-5 hours per weekend.

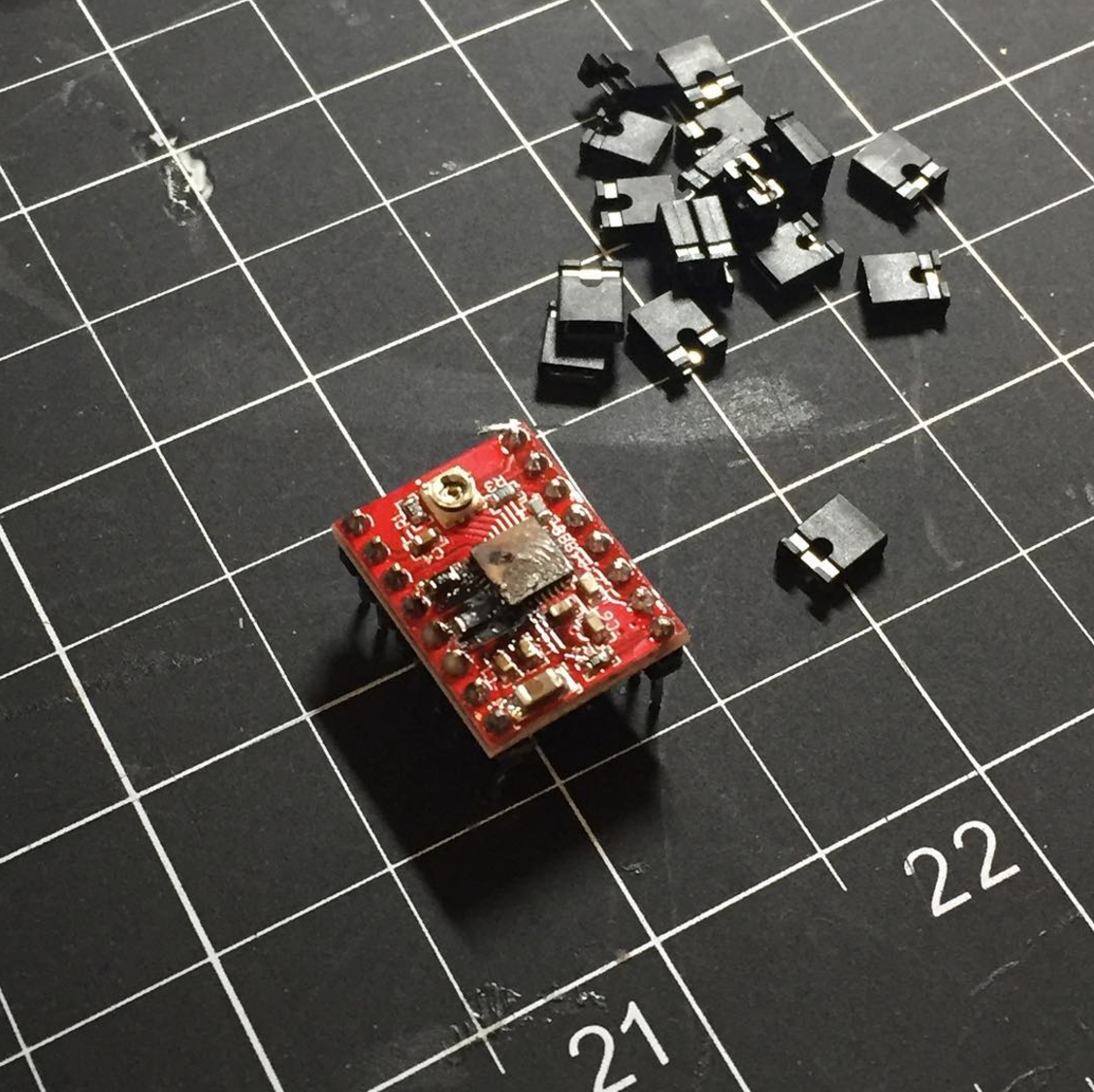

The kit came with a thumb drive of software and instructions. The latter was in Chinese and English; however, the English was lacking. Many lines read similar to “make like picture do.” I did alright following the pictures for the first part, assembly, but struggled with the wiring and boards. After I completed the build and uploaded the firmware, it wasn’t working quite right and I enlisted the help of my husband. We couldn’t track down the issue until a small fire started on one of the chips. Turns out, I forgot to put the jumpers between the chips and board. I still have no idea what they do, but immediately after replacing the burned-out chip and putting the jumpers where they belonged on the board, I could control my printer as expected from Repetier on my laptop.

The kit came with a thumb drive of software and instructions. The latter was in Chinese and English; however, the English was lacking. Many lines read similar to “make like picture do.” I did alright following the pictures for the first part, assembly, but struggled with the wiring and boards. After I completed the build and uploaded the firmware, it wasn’t working quite right and I enlisted the help of my husband. We couldn’t track down the issue until a small fire started on one of the chips. Turns out, I forgot to put the jumpers between the chips and board. I still have no idea what they do, but immediately after replacing the burned-out chip and putting the jumpers where they belonged on the board, I could control my printer as expected from Repetier on my laptop.

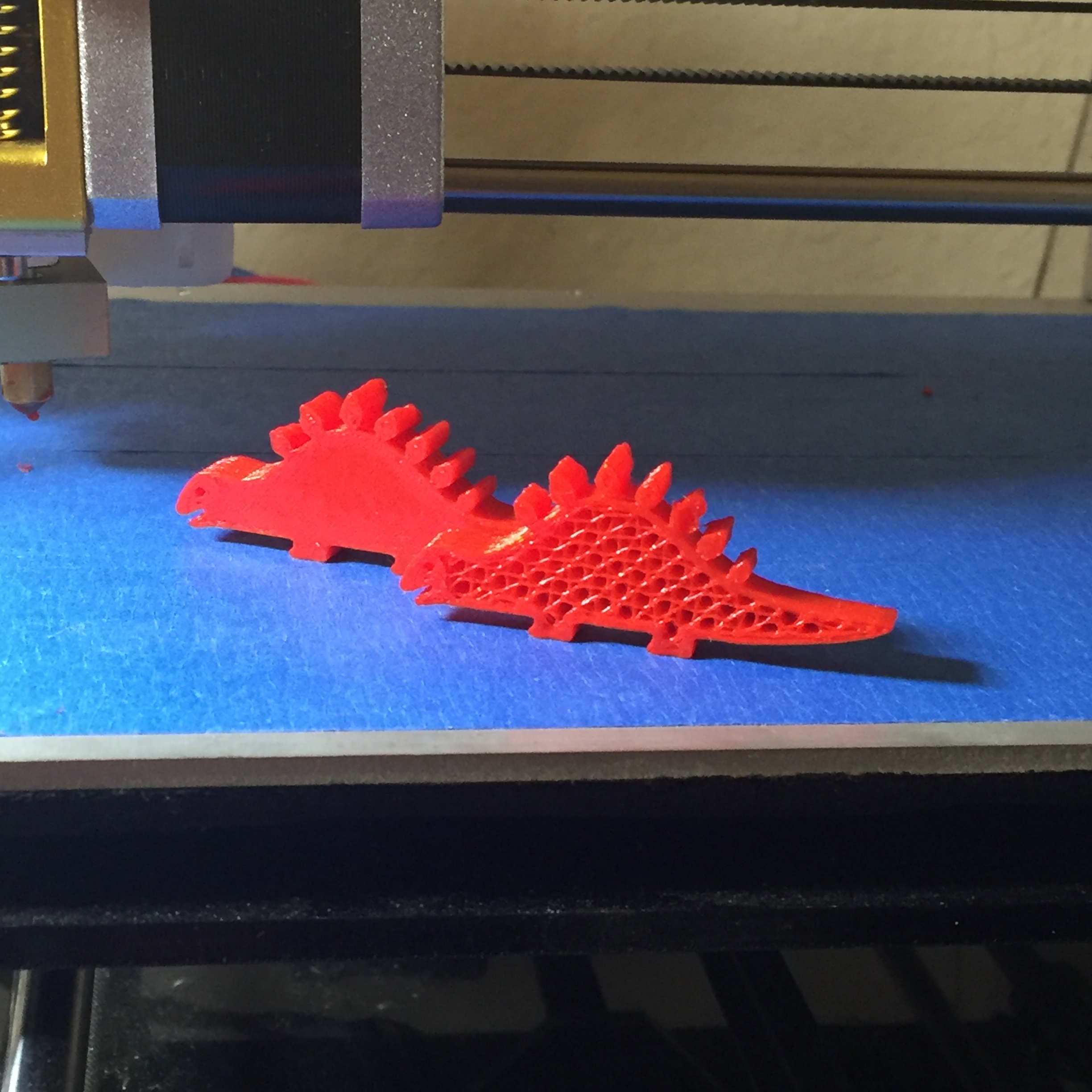

There are a few small upgrades I need to make sooner rather than later. The Arduino board is a knock-off and won’t work with the latest version of the firmware. I already have a new board to replace it with, but haven’t been eager to take my printer out of commission so soon after getting it running. Also, my printer can only print small items – items that can be printed 40 minutes or less. This has something to do with the extruder design. After 40 minutes, the filament becomes too hot up the line to feed properly into the extruder.

There are a few small upgrades I need to make sooner rather than later. The Arduino board is a knock-off and won’t work with the latest version of the firmware. I already have a new board to replace it with, but haven’t been eager to take my printer out of commission so soon after getting it running. Also, my printer can only print small items – items that can be printed 40 minutes or less. This has something to do with the extruder design. After 40 minutes, the filament becomes too hot up the line to feed properly into the extruder.

All in all, I’m very pleased with the whole endeavor. It was fun building up this machine and seeing how all the small parts worked together to complete complex computer instructions. This was my first experience doing anything with electronics or having to think about circuits outside of my computer assembly and architecture class. Lately, I’ve spent time printing items from Thingiverse while trying to make sense of the many slicer configurations and learning what you need to look out for to have a successful print. Up next on the agenda is learning how to create 3D objects on my computer to send to the printer.