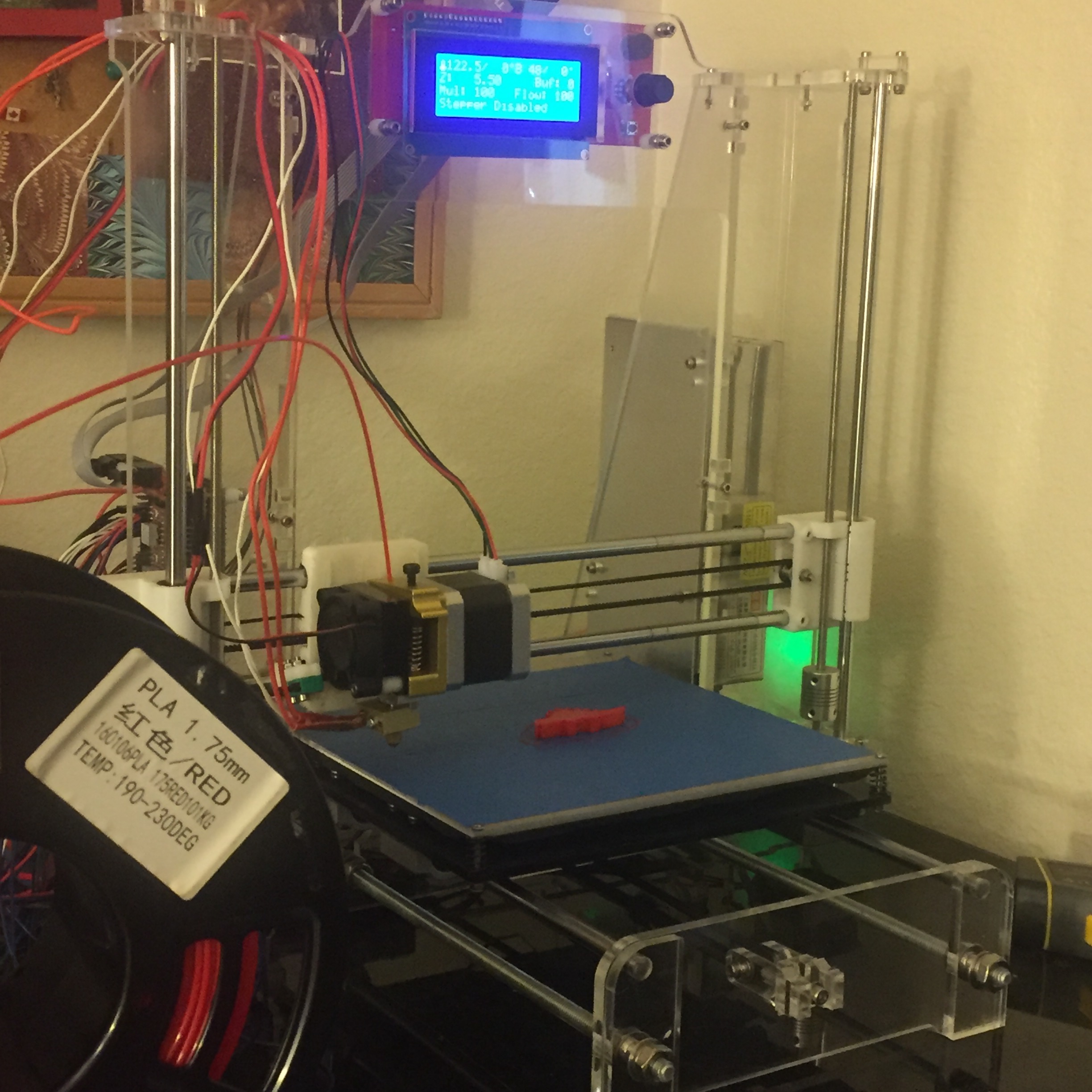

When the heated bed of my first 3d printer stopped working, it was the tiny push I needed to upgrade to an Original Prusa i3 MK3S. I had been eyeing them for a while. Now that I knew this hobby wasn’t a passing fancy I was ready to unlock more features and spend less time keeping my printer running and more time printing!

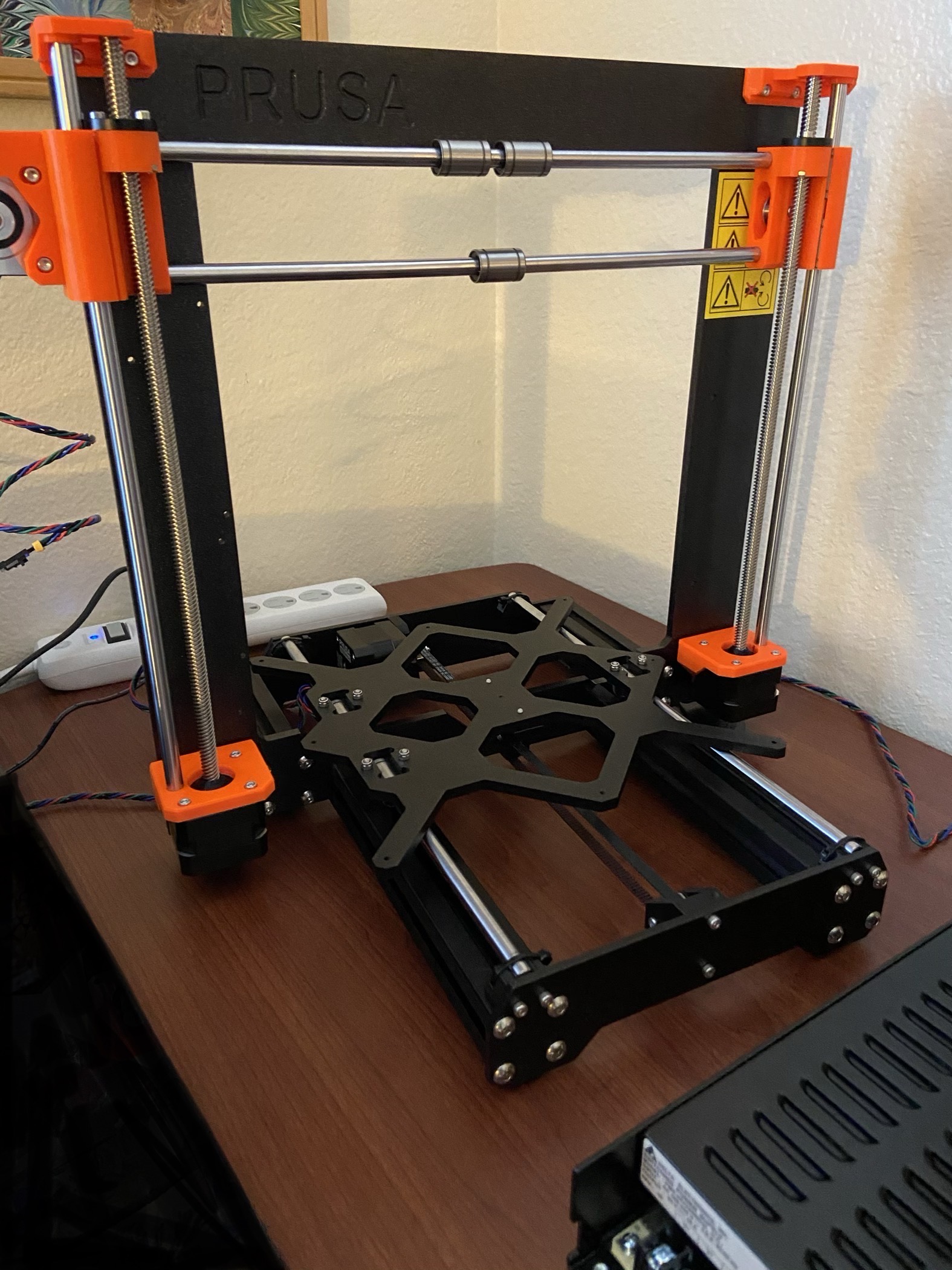

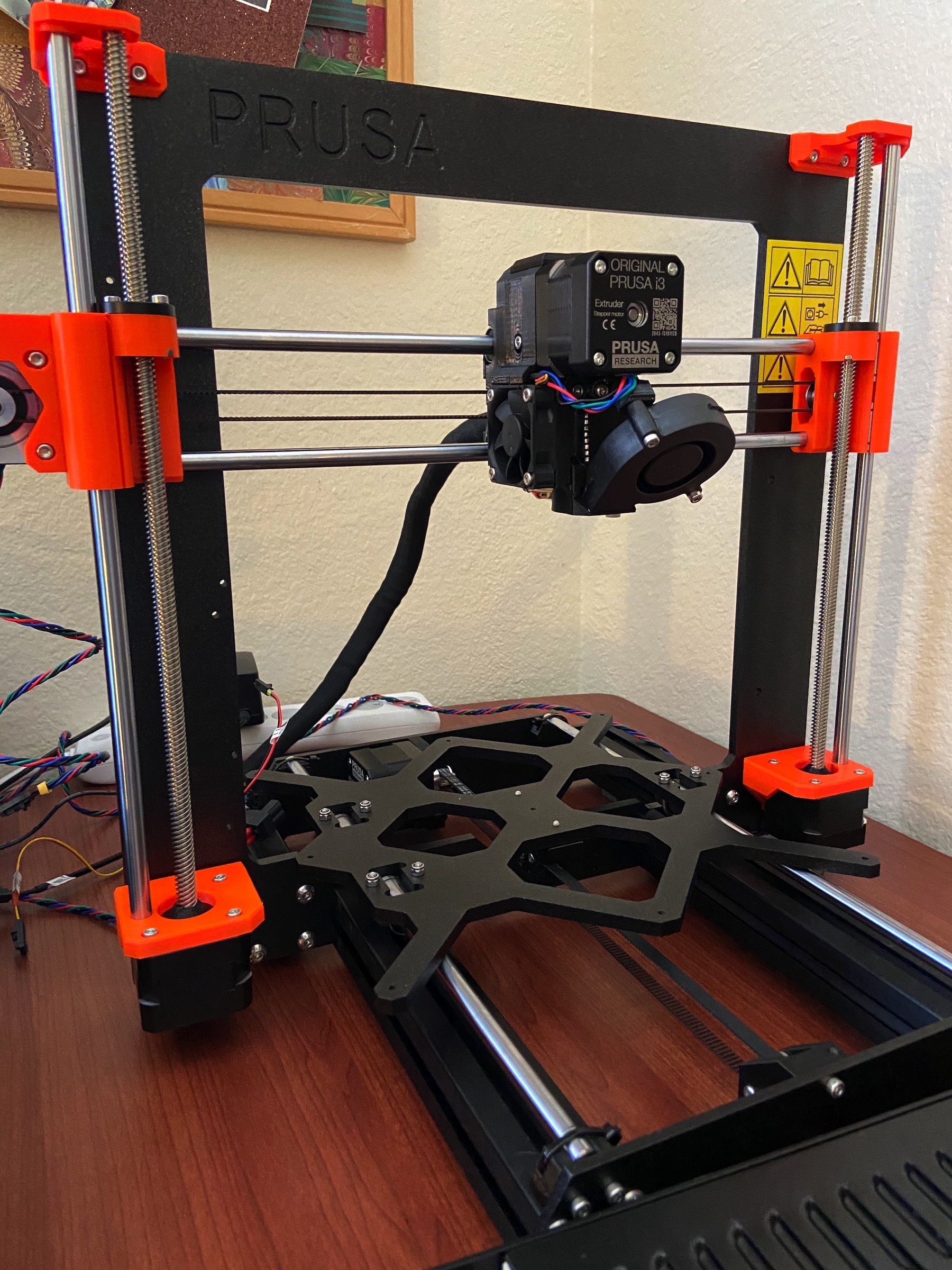

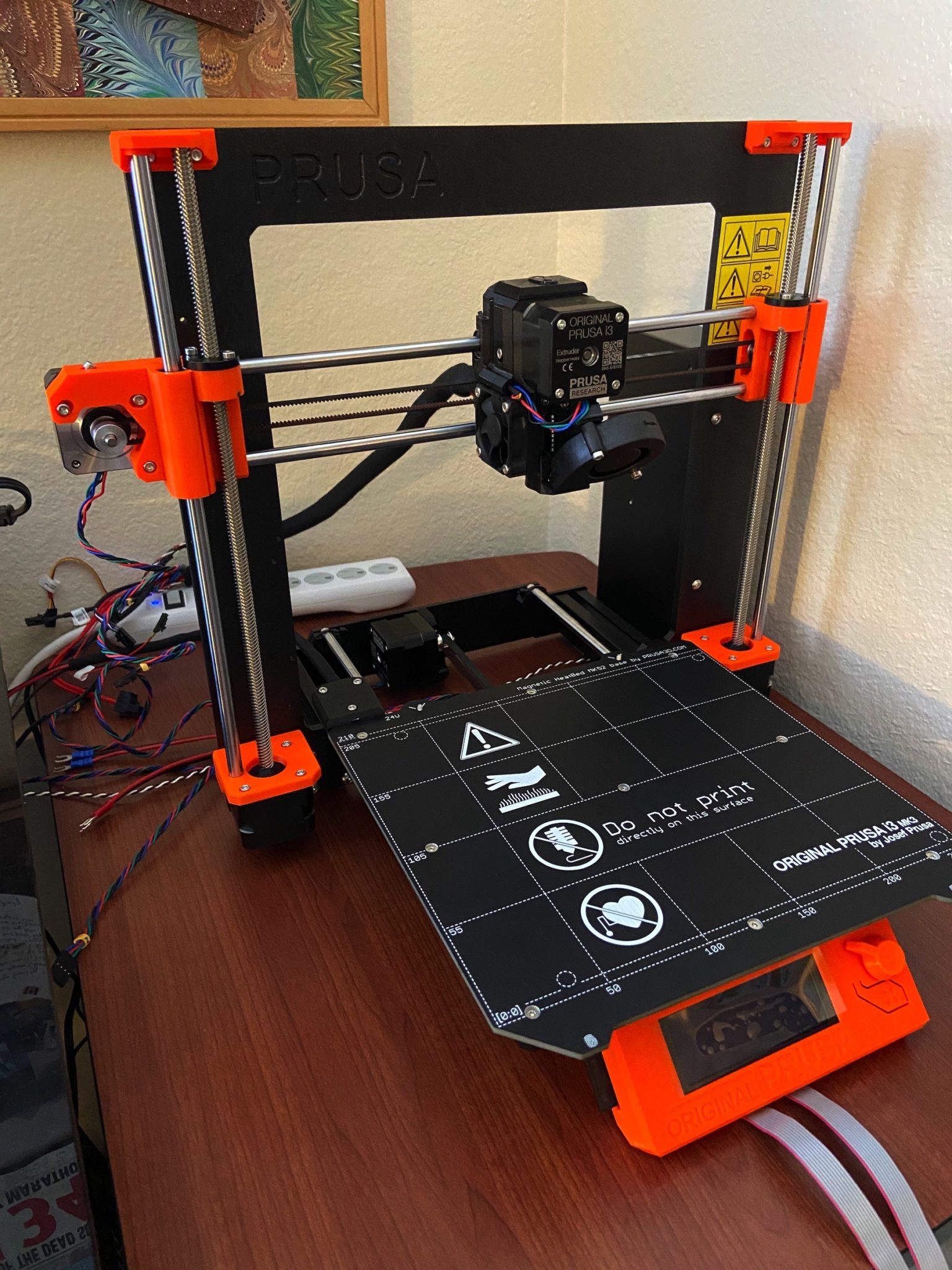

Assembly

I spent three mornings assembling the printer for a total of 15 hours. Other users report a faster build time, but I went slow and tried to learn more about the design and purpose of each part as I put them together. The kit comes with a detailed manual which is also available online. The online version has high quality photos you can magnify and comments from other users making the assembly friendly for anyone. I was impressed by the cable management. Getting the first layer calibrated is my least favorite part of printer ownership, however between the calibration tools installed on the printer and the guides and examples online, it wasn’t too difficult to prep the first print to have a solid foundation.

First Print

My very first print was a perfect benchy. This validated my decision to purchase this model. With my old printer, I had very few perfect prints and none were as complex as the benchy. The SD card is preloaded with gcode files ready for testing, so users don’t have to master PrusaSlicer at the same time.

Issues

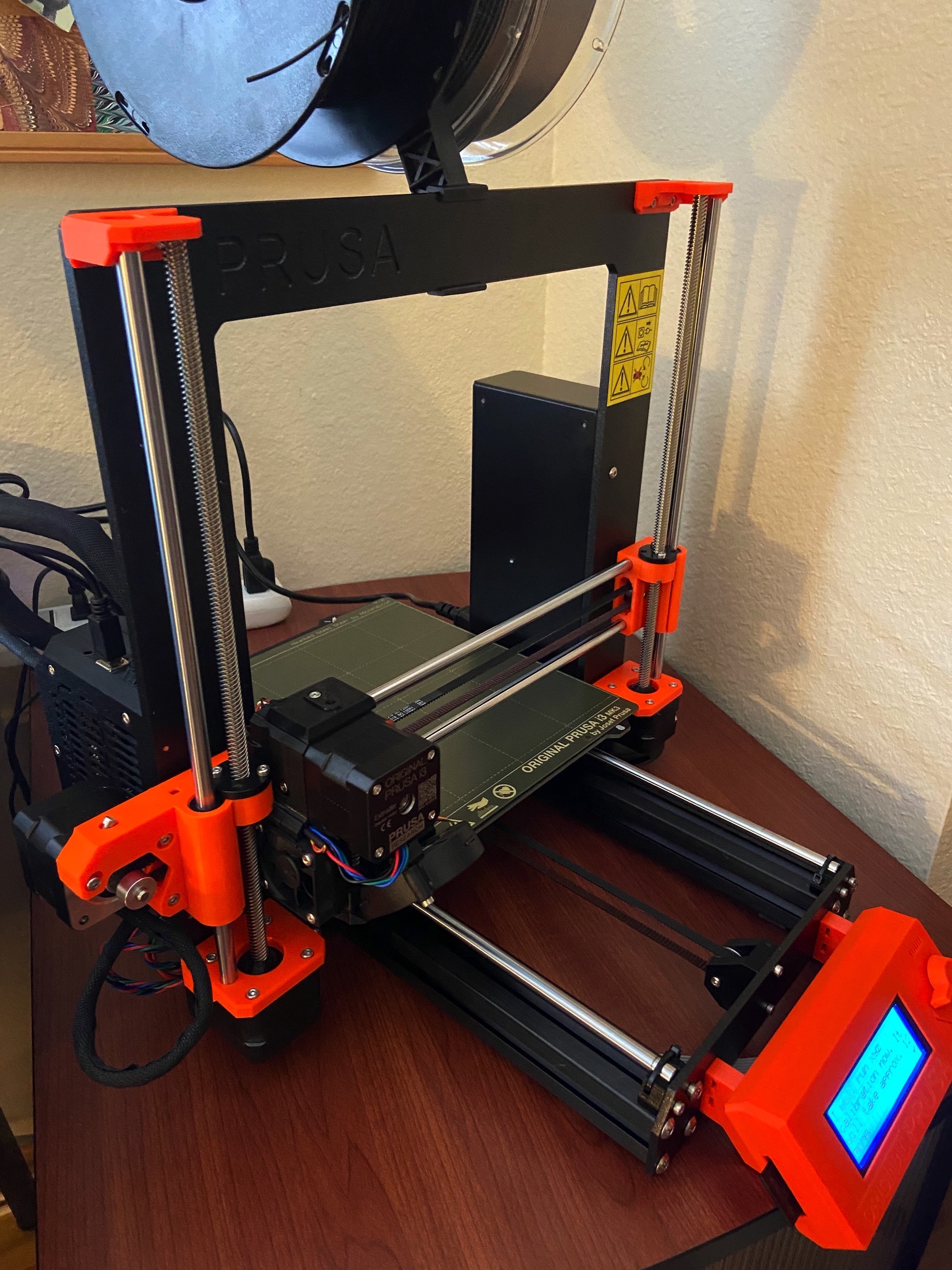

Finding space and selecting a table for the printer – Ideally, I would set my printer on a tall, sturdy, wooden table in a well ventilated room. But, I only have a few pockets of space in my house where my toddlers don’t have free rein. I selected a cart from 3D Up Fitters and bought the middle shelf to give it added stability. It vibrates, yet this doesn’t affect print quality as everything vibrates together. It is modular – they provide STLs for tool and filament holders you can print and add to the cart.

Noise – This model is noticeably quieter than my previous one, however it is still noisier than I would like due to my table selection. I also store my filament upright on the cart, so that rattles too.

Warping and elephant’s foot – This model does not come with an enclosure which is a must for larger prints. You can find many cheap, DIY enclosures online, but please be mindful about fire safety. The plastic tent and cardboard options hobbyists post online are alarming. The acrylic one I selected from 3D Up Fitters is better though not fireproof. I wanted to be able to see the print and add tool holders. It provides air to the power supply and has a fan to regulate the temperature.

Filament – Hatchbox PLA is the filament I use the most and gives me the least amount issues with clogging and print quality. I’ve tried shiny PLA and other brands, but stick to Hatchbox generally so I don’t need to troubleshoot filament related problems.

Troubleshooting & Maintenance

Belt tightening, rod lubing, clog removal, hot-end replacement, cleaning – I’ve done it all in the past two years. Prusa Research’s documentation and forums make it easy to diagnose your print and printer issues and correct them. You can order replacement parts from their website and they have customer support. However, I’ve never needed their customer support. Their self-help has been sufficient up until now.

Safety Features

Safety is at the forefront of my mind when working with my printer. I had a fire with my last printer and have two little kiddos who have claimed most of my house. I put a fire alarm on top of my case where the fan draws the air out and keep a fire extinguisher nearby. The printer itself has safety checks and shuts itself off in certain events. For example, I damaged one of the wires on the hotend and the printer shut off after sensing something was wrong.

I’ll leave the house with it running for short periods of time, but not a full work day. I’d like to rig up a fire suppression system under the enclosure and be able to cut the power remotely with a smart controlled power strip first.

Family Fun

Some of the first prints I did were to create food for my kids’ play kitchen. My daughter loved the muffin tin and the cupcakes I printed so much that she went to sleep with them, which is the highest compliment a child can give a toy.

Over one Christmas, we couldn’t leave the house because of a COVID exposure. We were watching Rudolph the Red-Nosed Reindeer and the Abominable Snowman puts a star on top of the tree at the end of the movie. This caused a major meltdown because we didn’t have a star for the top of our tree. Luckly, there was a nice star available from Thingiverse and Prusa saved Christmas!

Limitations

The limitations I have at the moment have more to do with my home situation than the actual printer. I’ve only used PLA filament. I have projects in mind that would require wood or ABS filament, but I want a better ventilation setup first. I’ve also not tried any overnight prints because it is located in the office nook of my bedroom.